Unlock the full potential of your dehydrator with The Ultimate Guide to Dehydrator Recipes! This comprehensive ebook is your go-to resource for crafting delicious, healthy, and long-lasting snacks and meals. Perfect for beginners and experienced dehydrating enthusiasts alike, this guide provides everything you need to know to boost your kitchen game.

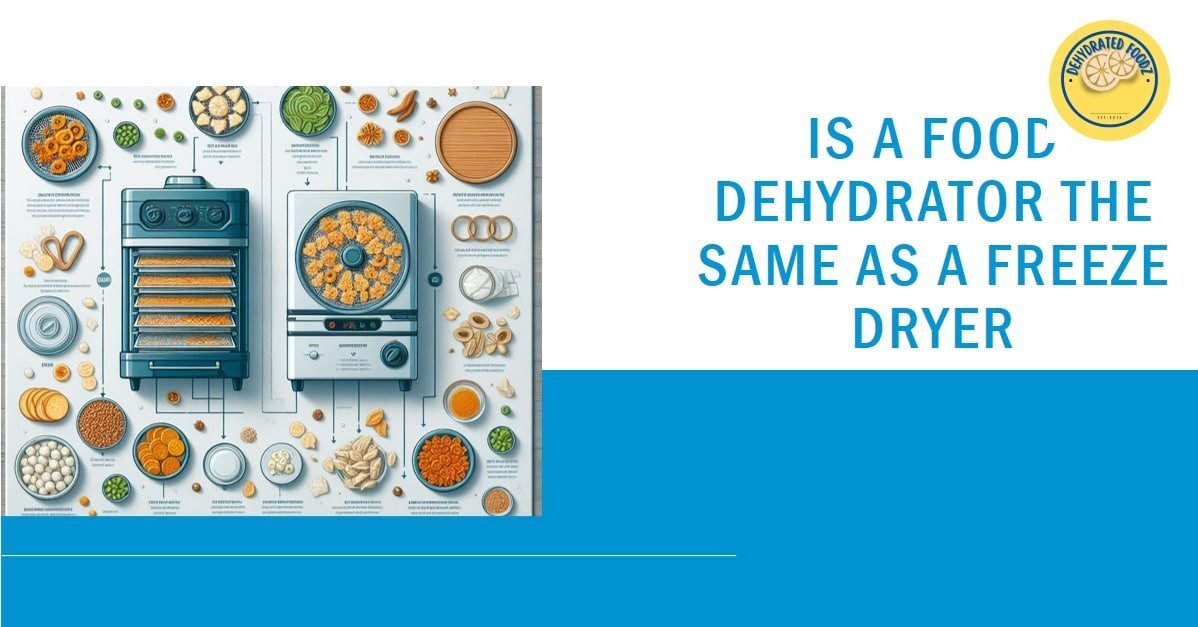

Is a Food Dehydrator the Same as a Freeze Dryer? Exploring Food Preservation Methods

If you’re exploring ways to extend the shelf life of your food, you might be considering a

Key Takeaways

Food dehydrators and freeze dryers are two different devices for food preservation, with dehydrators using low heat to eliminate moisture, while freeze dryers remove water through sublimation, retaining more nutrients and having a longer shelf life.

Freeze-dried foods can last over 25 years at room temperature and preserve a high degree of their original nutritional content, making them suitable for long-term storage and emergency preparedness.

While dehydrated foods typically have a shorter shelf life and can range in texture, they are more cost-effective than freeze dryers, with some dehydrated foods capable of lasting up to 25 years if vacuum sealed and stored properly.

Understanding Food Dehydrators

A food dehydrator is a nifty device designed to extend the shelf-life of ingredients by eliminating moisture from them through air circulation at a low temperature. Food dehydrators come in two main types: vertical and horizontal, further classified as stackable, shelf, or cabinet dehydrators.

Not only does a food dehydrator:

prevent the growth of harmful contaminants

help reduce food waste

provide an energy boost

When vacuum sealed, dehydrated food can have a shelf life of up to 25 years.

The Basics of Dehydrating Food

Dehydrating food involves the removal of moisture, usually by exposing it to low heat over a prolonged period. This process inhibits the growth of spoilage-causing microorganisms and slows down enzymatic reactions that can lead to spoilage. Typical temperatures used in food dehydration range from 120°F to 145°F (52°C to 63°C).

Before dehydration, ensure that you thoroughly wash all produce, use clean and sanitized equipment and utensils, and cook meats or poultry to a safe temperature to eliminate harmful bacteria.

Popular Foods for Dehydration

From fruits like bananas and apples to vegetables such as beans, broccoli, and squash, a wide range of foods can be dehydrated. Even meats like ground beef, chicken, ham, and tuna can be dehydrated, commonly used for making jerky. However, it’s worth noting that high-fat dairy products, like cheese, are not advisable for dehydration due to the risk of bacterial growth.

Dehydrator Equipment Essentials

When investing in a food dehydrator, you should take into account several key features. These include:

Heat distribution & air flow

Ease of use

Cost

Size and capacity

Noise levels

Wattage

The adjustability of the thermostat

Placement of the fan and heating elements

Temperature range

Tray shape

Construction materials

Power/speed

A higher power dehydrator can dry food faster and more efficiently.

Brands recommended for home use include:

Cuisinart

NutriChef

Aroma

LEM

Samson

Cosori

Nesco

Magic Mill

Tribest

Sedona Express

Premium Dehydrator

Dehydro Digital Electric

Dive into Freeze Drying Technology

Freeze drying, on the other hand, is a high-tech method that involves the sublimation of water, where it transitions directly from solid (ice) to vapor without passing through the liquid phase, effectively drying the food without damaging its structure. This method is used for a variety of food items, including:

meats

eggs

seafood

fruits

dairy products

Freeze-dried foods have several advantages:

They retain a significant portion of their nutritional content and phytochemicals, contributing to a healthy nutritional profile.

They have an extended shelf life and do not need refrigeration.

They are especially advantageous for long-term storage and emergency preparedness.

Freeze Drying Process Explained

The freeze-drying process involves freezing the food, then lowering the pressure and applying heat to remove the frozen water. This process takes place at temperatures ranging between -50 °C (-58 °F) and -80 °C (-112 °F), and then drying it at a recommended temperature range of 35-90° F, with the most efficient range being between 50-75° F.

This method is distinctly different from dehydration which involves the use of heat to eliminate moisture.

Advantages of Freeze Dried Foods

Freeze-dried foods, including freeze dried coffee, have a distinct edge over other preservation methods as freeze dried food retains most of their nutritional content and phytochemicals, contributing to a healthier choice compared to foods preserved by other drying techniques. Plus, they have an extended shelf life of over 25 years at room temperature, providing a significant advantage for long-term food storage.

Their lightweight and compact nature facilitate easier storage, handling, and transportation.

The Machinery Behind Freeze Drying

To initiate the process of freeze-drying food at home, essential equipment includes:

A freeze dryer

A vacuum pump

Oil for the vacuum pump

A heavy-duty cart for mobility

Additional trays

Silicone mats for the trays

Mylar bags for storing the freeze-dried food

A freeze drying machine’s main components include:

A vacuum chamber to facilitate low-pressure conditions

Hollow shelves that aid in freezing and heating

A refrigeration system to achieve the low temperatures required for the initial freezing phase.

Comparing Preservation Outcomes

Now that we’ve got a grasp on both freeze drying and dehydration, let’s put them side by side and compare their outcomes. While both methods aim to prolong the shelf life of food, they result in different textures, nutritional values, and shelf life.

Freeze-dried food typically has a porous, airy texture that feels prone to crumbling when squeezed, whereas dehydrated food can range from leathery to crispy or chewy in texture. In terms of nutritional value, freeze-dried foods retain a significant portion of their nutritional content and phytochemicals, making them a healthier choice compared to foods preserved by other drying techniques.

When it comes to shelf life, freeze-dried foods boast an impressive average shelf life of over 25 years at room temperature, while dehydrated foods typically range from 1 year for fruits to about 6 months for vegetables at 60°F. However, with proper storage, some dehydrated foods can also last up to 25 years.

Texture: Chewy or Crispy?

The texture of preserved food can vary significantly between freeze drying and dehydration. Freeze-dried foods are known for their spongy, smooth, and firm texture. The crispy texture of freeze-dried foods is due to the removal of nearly all the moisture during the freeze drying process.

On the other hand, dehydration can lead to a range of textures, from leathery and pliable to crisp and brittle, depending on the food and dehydrating conditions.

Nutritional Value Face-Off

When it comes to preserving the nutritional value of food, freeze drying is the clear winner. Freeze-dried foods are known for preserving the majority of nutrients and phytochemicals, making them a healthier choice compared to foods preserved by other drying techniques. On the other hand, the method of food preservation does not have a significant impact on the caloric value of foods.

Shelf Life Showdown

Freeze-dried foods typically have an impressive average shelf life of over 25 years if stored in optimal conditions, while dehydrated foods can also last a long time with some lasting up to 25 years when properly stored. The shelf life of both depends on factors such as temperature, moisture, and oxygen levels.

With proper storage, freeze-dried items could potentially last up to 25-30 years and dehydrated foods typically ranging from 5-15 years.

Storage Solutions for Preserved Foods

Maintaining the quality and longevity of freeze-dried and dehydrated foods requires proper storage. Recommended container options for storing preserved foods include:

FoodSaver Jar Sealers

Mylar bags

Food-grade buckets

Vacuum-sealed containers for freeze-dried foods

Airtight containers such as mason jars with canning lids or freezer bags for dehydrated foods

Oxygen absorbers also play a crucial role by attracting and retaining oxygen within a sealed container, effectively safeguarding dry foods from insect damage and prolonging their quality over time.

As for the storage conditions, dehydrated foods should be stored in a cool, dark place to maintain quality, with a potential shelf life ranging from several months to a year. Freeze-dried foods can remain viable for 20-30 years when stored under suitable conditions. When it comes to space, dehydrated foods usually shrink in size by up to 50%, making them more efficient in terms of space. On the other hand, freeze-dried foods maintain their original size but are lighter, which can be advantageous for storage and portability.

Airtight Containers and Oxygen Absorbers

Creating a barrier against moisture and air, airtight containers play a pivotal part in food preservation. They:

Prevent spoilage while preserving the freshness, quality, flavor, and texture of the food

Provide protection against pests such as bugs and mice

Help prevent contamination from other sources

Oxygen absorbers are significant in preserving the quality of food by eliminating dissolved oxygen from the storage container. This action helps prevent spoilage and preserves the:

color

texture

aroma

natural freshness

Incorporating fresh food into one’s diet can help preserve food, thereby extending their shelf life.

Space Considerations: Freeze Drying vs. Dehydrating

In terms of storage, freeze-dried food takes up significantly less space than its fresh or dehydrated counterparts. The type of food can have an impact on the required storage space. Freeze-dried foods generally occupy much less space than their fresh or dehydrated forms, but the degree of reduction can differ based on the specific food being processed.

Dehydrated foods should be stored in a cool, dark space in airtight containers with good ventilation to maintain their quality.

Cost and Efficiency: What You Need to Know

Food preservation extends beyond merely prolonging the life of food, it also encompasses cost and efficiency. Here are some cost comparisons:

The average cost of a food dehydrator is approximately $15.

The average cost of a freeze dryer ranges from $3,599.00 to $4,395.00.

Operational costs: a 700W food dehydrator may cost around 6.5 cents per hour to run, while freeze dryers typically use around 725 Watts of power, which can result in a daily cost of $1.00-$2.80 depending on local power rates.

In terms of food processing capacity, dehydrators are able to process between 20 to 100 kg of food per batch, while freeze dryers can handle 6 to 10 lbs (2.7 to 4.5 kg) per batch, with the capacity to freeze dry up to 1,800 lbs (816 kg) or more of food annually.

Initial Investment: Comparing Costs

The average cost of a home food dehydrator ranges from $15 to $100, whereas the average cost of a home freeze drying machine falls between $2,900 and $3,895, showing a notable disparity in initial investment expenses. Food dehydrator prices can differ significantly among various brands and models.

For instance, the Magic Mill

Operational Expenses

The typical maintenance cost for a food dehydrator can range from $10 to $15, whereas the maintenance costs for a freeze dryer can vary but are a significant component of the total operational expenses. The operation of a food dehydrator is generally considered inexpensive due to the relatively low electrical costs involved in the food production process.

On average, a freeze dryer typically uses about 10 amps (1500 watts) of power per hour, indicating a significant electricity usage that contributes to the machine’s operational costs.

Versatility and Application

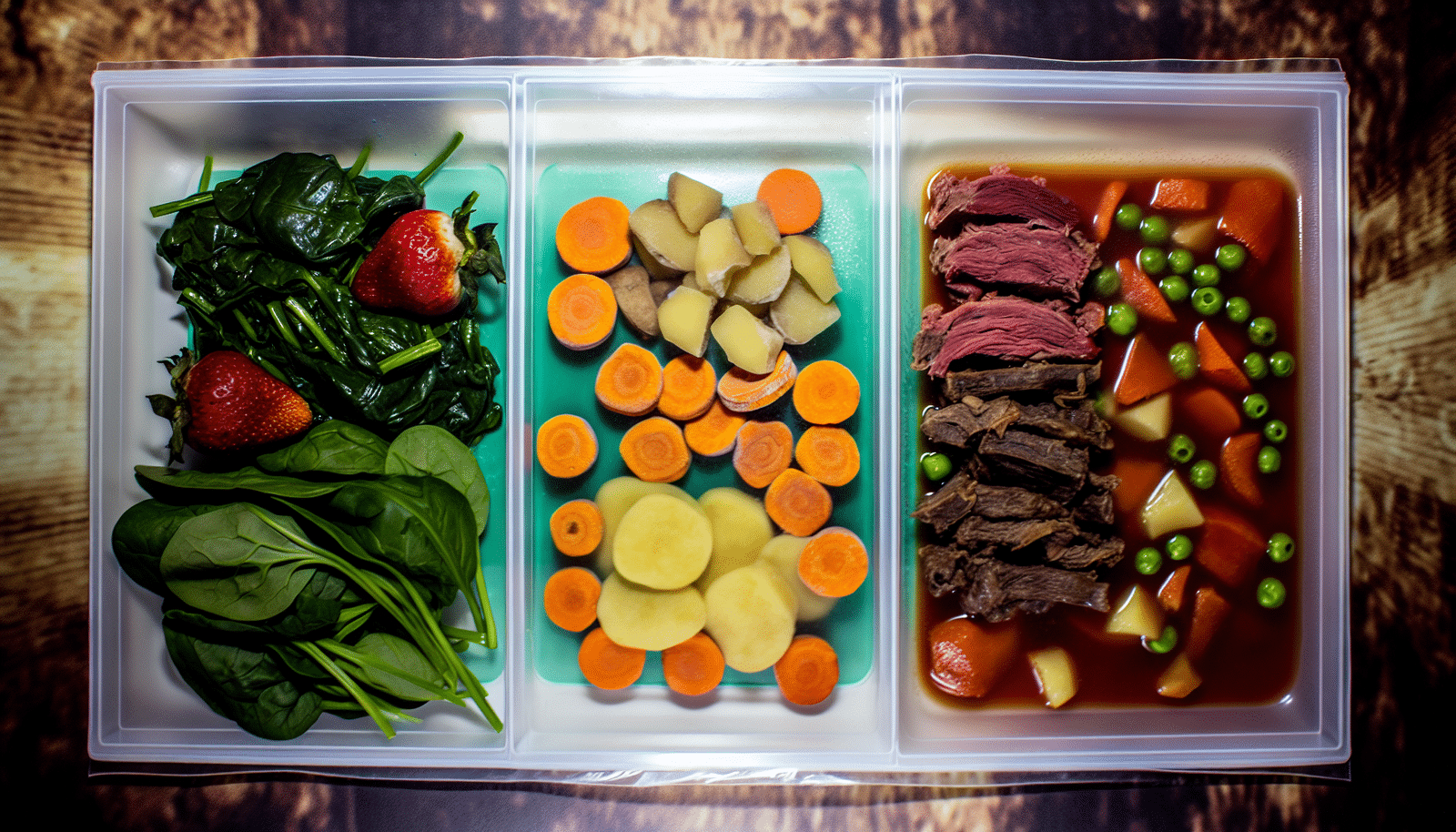

Both freeze drying and dehydration methods offer extensive versatility. A variety of foods can be preserved through these methods, including meats like tuna, salmon, and shrimp, dairy products like cheese, and fruits like strawberries, blueberries, and bananas. The tangible benefits extend beyond preserving food to include a reduction in food wastage and the potential to save money in the long run.

Complete meals can be preserved through both freeze drying and dehydrating methods. This preservation technique enables a diverse range of culinary applications and supports meal planning for activities like camping and emergency preparedness. The constraints of freeze drying and dehydrating foods include:

The necessity of water to reconstitute freeze-dried food

The slow process of freeze drying

Texture changes to a dry and styrofoam-like state

Different textures compared to dehydrated food

The high cost associated with home freeze-drying units.

From Fresh Produce to Prepared Meals

From fresh produce to complete meals, both freeze drying and dehydrating have you covered. While most foods can be freeze-dried, there are some exceptions such as:

honey

mayonnaise

butter

nuts

nut butters

pure chocolate

syrups

jams and preserves

Prepared meals can be effectively preserved through both freeze drying and dehydrating methods. Freeze-dried meals can rehydrate in approximately 5 minutes with cold or warm water, whereas dehydrated meals may take 10-20 minutes for rehydration.

Special Cases: When to Freeze Dry or Dehydrate

While both methods are versatile, there are specific foods and situations that may require one preservation method over the other. Foods such as:

cucumber

iceberg lettuce

celery

radishes

various fruits like peaches, strawberries, and watermelon

are better suited for dehydration. These items, along with other vegetables such as broccoli, cabbage, and cauliflower, can attain desirable textures like being leathery, crispy, or chewy after dehydrating.

On the other hand, freeze drying, a process in which freeze drying foods originates, is advantageous for maintaining texture, nutrition, and preserving larger food pieces with a longer shelf life.

The Environmental Impact of Food Preservation

Beyond prolonging the shelf life of food, preservation also plays a role in sustainability and reducing our carbon footprint. The energy consumption for a freeze dryer is approximately 990 to 1500 watts per hour, with a daily cost of about $1.00-$2.80. Food dehydrators generally consume less energy compared to freeze dryers, although the exact consumption can vary.

Moreover, food preservation through dehydration or freeze drying has a significant impact on managing waste and its environmental impact by extending the shelf life of food. This reduction in food waste helps conserve resources and energy. Studies have shown that the shelf life extension can prevent about 50 percent of consumer food waste, and frozen foods can reduce food waste by six-fold compared to fresh foods.

Innovations in Food Preservation

The realm of food preservation is far from static, it is constantly advancing and innovating. Some of the most recent advancements in food preservation technology include:

Freeze-drying

High-pressure processing

Pulsed electric field processing

Ultrasonic processing

Cold plasma processing

Electrical heating

Fermentation

Extrusion

Aseptic processing

Advancements in dehydration technology include innovations such as photovoltaic, thermal imaging, microwave-assisted, and hybrid technologies. Additionally, methods like osmotic dehydration, vacuum drying, superheated steam drying, heat pump drying, and spray drying have further improved the efficiency and quality of food dehydration.

In addition, AI and robotics play a significant role in modern food preservation by contributing to:

Supply chain management

Quality control

Predictive analytics

Personalized nutrition

Food storage and shipment management

Improving agricultural efficiency through smart and robotic farming techniques, including the use of drones.

Summary

In conclusion, both freeze drying and dehydration offer effective ways to preserve food, each with its unique advantages and considerations. While freeze drying is known for its superior preservation of nutritional value and longer shelf life, dehydration is a more affordable and accessible option. Regardless of your choice, both methods open up new possibilities in food storage and waste reduction, ultimately contributing to a more sustainable future.

Frequently Asked Questions

Can you freeze dry candy without a freeze dryer?

Yes, you can freeze-dry candy in a regular freezer by allowing the moisture to freeze and then separating it from the candy as it melts at room temperature. This will leave you with a crunchy, chewy candy treat.

What can I use instead of a freeze dryer?

You can use your household freezer as an alternative to a freeze dryer, although it will take longer to achieve similar results. This approach can be cost-effective and yields satisfactory outcomes.

Can you freeze-dry with a dehydrator?

No, you can’t freeze-dry with a dehydrator as they are different processes with different results. While a

Which is better dehydrated or freeze dryer?

In conclusion, freeze-dried food retains about 97% of its nutrients, making it a better option compared to dehydrated food which retains only 60-75% of the original nutrients.

What are the benefits of using a food dehydrator ?

Using a food dehydrator can extend the shelf-life of ingredients, prevent harmful contaminants, create healthy foods, reduce waste, preserve nutrients, and provide an energy boost. It’s a great way to make the most of your food and reap health benefits.