Food Dehydrator vs Filament Dryer: Key Differences

We will compare

Key Takeaways

- Food dehydrators are used to remove moisture from food, while filament dryers are used to dry 3D printing filaments.

- Food dehydrators are versatile and can be used for a variety of foods, while filament dryers are limited to drying 3D printing filaments.

- Both food dehydrators and filament dryers have their unique benefits, and the choice between the two depends on factors such as cost, efficiency, and specific needs.

- What are They and How Do They Work?

- Uses of Food Dehydrators

- Uses of Filament Dryers

- Comparison of Food Dehydrators and Filament Dryers

- Factors to Consider When Choosing Between the Two

- Frequently Asked Questions

- What is the difference between a food dehydrator and a filament dryer?

- Can I use a food dehydrator as a filament dryer?

- What are the advantages of using a food dehydrator over a filament dryer?

- Is a filament dryer more efficient than a food dehydrator?

- Can I use a filament dryer to dehydrate food?

- Which is a better investment, a food dehydrator or a filament dryer?

What are They and How Do They Work?

Filament is a thin, flexible plastic strand used as “ink” for Fused Deposition Modeling (FDM) 3D printers. It is typically made from materials like PLA, PETG, ABS, or Nylon. 3D printing utilizes filament to create objects layer by layer for purposes like prototyping, manufacturing, and art.

General Overview: What is a Food Dehydrator ?

A

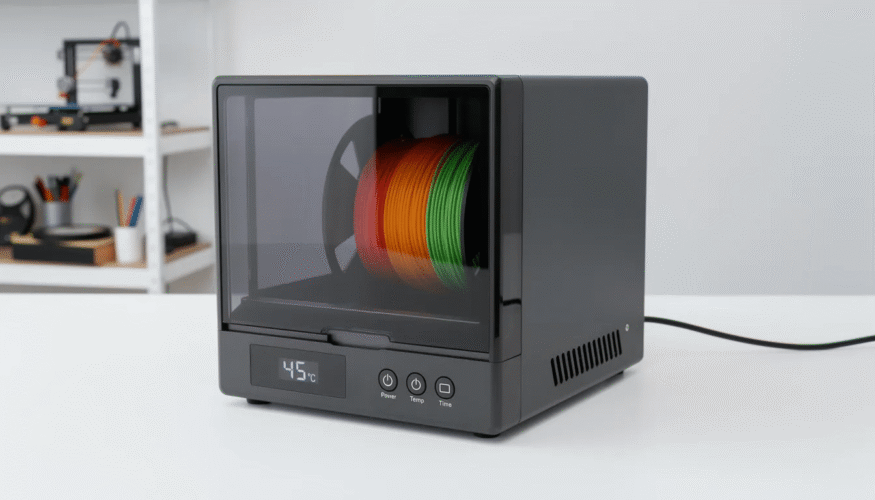

General Overview: What is a Filament Dryer?

A filament dryer is specifically designed for 3D printing and typically includes features like spool holders and humidity sensors. Its main function is to dry 3D printing filaments such as PLA, PETG, ABS, and nylon, which are prone to absorbing moisture from the air. Filament dryers often have exit ports for printing directly from the dryer and are optimized for maintaining the ideal conditions for filament storage and use.

How Food Dehydrators Work

Food dehydrators function by providing consistent airflow and regulated temperatures to effectively eliminate water content from food items. They use multiple trays to allow for drying several items—or spools of filament—at the same time. The process involves:

- Circulating heated air at a set temperature (typically 40°C–70°C)

- Removing moisture from the food or filament

- Preserving the nutritional integrity and flavor of edibles

How Filament Dryers Work

Filament dryers, such as the EIBOS 3D Series X, operate by administering controlled heat and airflow to spools of filament. They safeguard the optimal moisture levels of materials like PLA, PETG, and ABS. Many filament dryers include:

- Spool holders for easy loading and unloading

- Humidity sensors to monitor moisture levels

- Exit ports for printing directly from the dryer

- Vacuum or drybox features for enhanced moisture removal

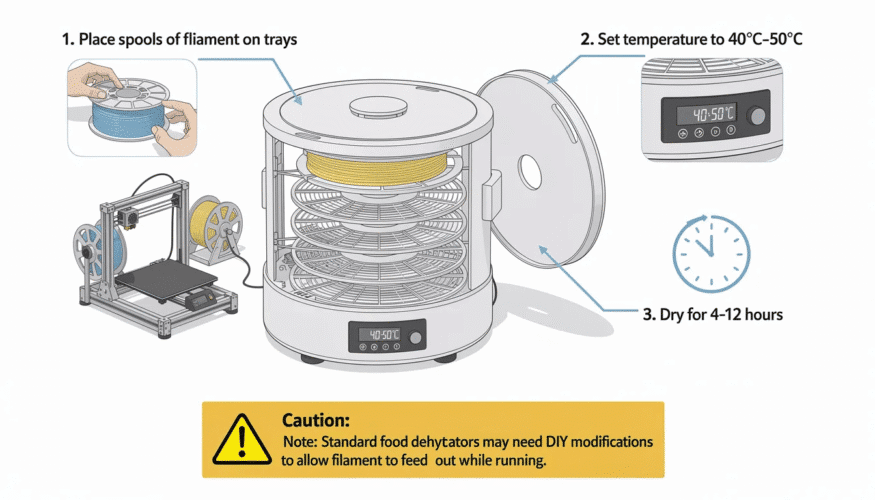

Drying Filament with a Food Dehydrator

- Place spools of filament on the trays inside the dehydrator.

- Set the temperature to a safe level (usually between 40°C–50°C for most filaments).

- Monitor the drying time, which can range from 4 to 12 hours depending on the material and moisture content.

- Note: Standard food dehydrators require DIY modifications to allow filament to feed out while the unit is running.

Drying Filament with a Filament Dryer

- Load the filament spool into the dryer.

- Set the appropriate temperature and drying time based on the filament type.

- Use the exit port to print directly from the dryer if desired.

- Monitor humidity levels using built-in sensors.

By understanding the mechanisms and applications of both devices, you can choose the best drying method for your needs.

Now that we’ve covered what food dehydrators and filament dryers are and how they work, let’s explore the specific uses of food dehydrators.

Uses of Food Dehydrators

Food dehydrators, exemplified by the Chefman

Common Applications and Benefits of Food Dehydrators

- Drying fruits, vegetables, and meats for long-term storage

- Preserving herbs, flowers, and artisanal materials like clay or potpourri

- Creating healthy, shelf-stable snacks without refrigeration

- Drying multiple spools of 3D printing filament at once due to multiple trays

- Cost-effective and versatile alternative to specialized filament dryers

Advantages:

- Extends the shelf life of food items

- Enhances material quality by reducing moisture content

- Allows for batch processing of multiple items or spools

- Retains more nutrients in food compared to some other drying methods

Steps for Drying Filament with a

- Place filament spools on dehydrator trays.

- Set the temperature (typically 40°C–50°C).

- Dry for 4–12 hours, depending on filament type and moisture level.

- Consider DIY modifications if you want to print directly from the dehydrator.

This versatile apparatus stands as a valuable instrument for individuals with an interest in preserving and relishing natural products conveniently and in dehydrating food for lightweight, long-term storage.

Now that we’ve explored the uses of food dehydrators, let’s look at how filament dryers are used in 3D printing.

Uses of Filament Dryers

Filament dryers are purposefully engineered to safeguard 3D printing filament spools against moisture absorption, a factor that can compromise print quality. Through the application of regulated heat and, in some cases, vacuum pumps within a vacuum chamber, these dryers maintain the dryness of filament varieties such as PLA, PETG, ABS, and nylon—nylon being particularly hygroscopic and prone to absorbing moisture from the air.

Common Applications and Benefits of Filament Dryers

- Drying 3D printing filaments to prevent print defects

- Maintaining optimal moisture content for consistent print quality

- Reducing issues like bubbles, stringing, brittleness, and poor adhesion

- Enhancing layer adhesion and reducing the occurrence of clogs

- Allowing direct printing from the dryer via exit ports

Advantages:

- Designed specifically for 3D printing filaments

- Includes features like humidity sensors and spool holders

- Provides precise temperature and humidity control

- Reduces the risk of filament degradation and print failures

Steps for Drying Filament with a Filament Dryer:

- Load the filament spool into the dryer.

- Set the correct temperature and drying parameters for the filament type.

- Use the exit port to print directly from the dryer if needed.

- Monitor humidity and dryness using built-in sensors.

Filament dryers find common applications in various industrial domains, including prototyping, the creation of functional prototypes, the fabrication of architectural models, and the production of intricate mechanical components.

With a clear understanding of how both devices are used, let’s compare their key differences and similarities.

Comparison of Food Dehydrators and Filament Dryers

Although food dehydrators and filament dryers both operate by extracting moisture through controlled temperature and airflow, their performance, drying time, and suitability for 3D printing materials differ. For food applications, it can also be helpful to understand how food dehydrators compare to ovens for drying food.

Comparison Table: Food Dehydrator vs Filament Dryer

| Feature/Aspect | Food Dehydrator | Filament Dryer |

|---|---|---|

| Primary Use | Removing moisture from food items | Drying 3D printing filaments |

| Can Dry Multiple Spools | Yes, due to multiple trays | Usually limited to 1–2 spools at a time |

| Direct Printing Capability | Requires DIY modifications for filament feed-out | Typically has exit ports for direct printing |

| Cost | Budget-friendly alternative | Higher initial investment |

| Temperature Control | Consistent, low-heat environment (40°C–70°C) | Precise, filament-specific temperature and humidity control |

| Humidity Sensors | No | Yes |

| Spool Holders | No (requires improvisation) | Yes |

| Versatility | Can be used for food and filament | Designed for filament only |

| DIY Modifications Needed | Yes, for filament feed-out and optimal use | No |

Key Differences and Similarities:

- Food dehydrators can dry multiple spools at once due to multiple trays.

- Food dehydrators require DIY modifications to allow filament to feed out while running.

- Filament dryers typically have exit ports for printing directly from the dryer.

- Food dehydrators are a budget-friendly alternative, creating a consistent, low-heat environment for drying filaments.

Both devices play a critical role in ensuring that the materials they treat remain devoid of excessive moisture, which could result in degradation or spoilage.

To rid filament of moisture, both heat and vacuum drying methods are used, but it is important to note that moisture lost during drying can be reabsorbed if filaments are not stored properly. Best practices are to store filaments in vacuum-sealed bags with desiccant packs to help prevent moisture absorption.

With these differences in mind, let’s move on to the factors you should consider when choosing between a

Factors to Consider When Choosing Between the Two

When deciding between a food dehydrator and a filament dryer, it is imperative to take into account variables such as cost, efficiency, and the particular needs of the materials undergoing drying.

Cost, Efficiency, and Other Considerations

- Cost: Food dehydrators are typically more budget-friendly upfront, while filament dryers require a higher initial investment.

- Efficiency: Filament dryers offer more precise temperature and humidity control, which can lead to better print quality and less wasted filament.

- Versatility: Food dehydrators can be used for both food and filament, while filament dryers are specialized for 3D printing.

- DIY Modifications: Food dehydrators may require modifications for optimal filament drying and direct printing.

- Odor and Ventilation: Food dehydrators can emit odors when drying filament; use in a well-ventilated area.

- Energy Use: Filament dryers may be more energy-efficient over time, but food dehydrators are cost-effective for occasional use.

Additional Tips:

- Use desiccants or moisture-absorbing agents to maintain filament dryness after drying.

- Monitor temperature settings to avoid damaging filament.

- Consider combining drying techniques (e.g., vacuum and heat) for best results.

Understanding these factors will help you make an informed decision based on your specific needs and budget.

Next, let’s address some frequently asked questions about food dehydrators and filament dryers.

Frequently Asked Questions

What is the difference between a food dehydrator and a filament dryer?

A food dehydrator is specifically designed to remove moisture from food items, while a filament dryer is used to dry filament for 3D printing purposes.

Can I use a food dehydrator as a filament dryer?

No, a food dehydrator does not have the necessary features to properly dry filament and may cause damage to the material.

What are the advantages of using a food dehydrator over a filament dryer?

A food dehydrator is more versatile and can be used for a variety of food items, while a filament dryer is specifically designed for drying filament only.

Is a filament dryer more efficient than a food dehydrator ?

Yes, a filament dryer is designed with specific temperature and airflow settings to efficiently dry filament, while a food dehydrator may not have the same precision.

Can I use a filament dryer to dehydrate food?

No, a filament dryer is not suitable for dehydrating food as it does not have the necessary temperature settings and may contaminate the food with plastic particles.

Which is a better investment, a food dehydrator or a filament dryer?

It depends on your needs. If you primarily want to dry food, a food dehydrator would be a better investment. If you are a frequent 3D printer, a filament dryer would be a more useful tool.