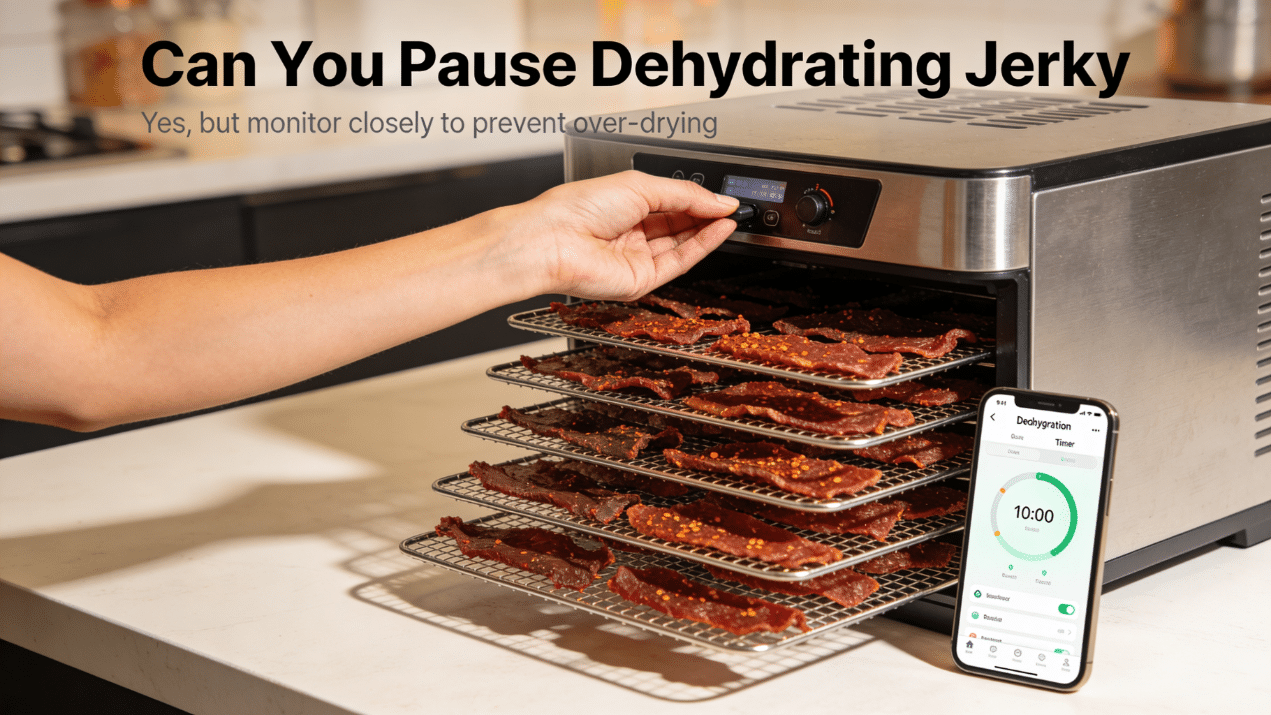

Can You Pause Dehydrating Jerky? (Safety, Timing, and Best Practices)

Making jerky at home is one of the most rewarding ways to preserve meat, but life doesn’t always cooperate with your dehydrator’s timeline. Whether you’re staring down an unexpected errand, a late-night batch that’s running longer than expected, or simply need to step away, you’re probably wondering if you can hit pause without ruining your jerky—or worse, making it unsafe to eat.

The short answer is yes, but the details matter enormously when you’re working with raw meat.

- Quick Answer: Is It Safe to Pause Dehydrating Jerky?

- Understanding Jerky Dehydration and Food Safety

- When (and How Long) Can You Safely Pause Dehydrating Jerky?

- How to Pause Dehydrating Jerky Safely

- How to Resume Dehydrating Jerky After a Pause

- Common Mistakes When Pausing Jerky Dehydration

- Special Considerations: Ground Meat Jerky vs. Whole Muscle Jerky

- Planning Your Jerky Dehydration to Avoid Pauses

- How to Tell When Jerky Is Fully Done (So You Don’t Need to Pause)

- FAQs About Pausing Jerky Dehydration

- Can I turn off the dehydrator while I run errands?

- Is it okay to pause jerky overnight in the fridge and restart in the morning?

- What if I accidentally left my dehydrator off for several hours?

- Can I finish jerky in the oven instead of restarting the dehydrator?

- How do I know if paused jerky has spoiled?

- Conclusion: Best Practices for Safe Jerky Dehydration Pauses

Quick Answer: Is It Safe to Pause Dehydrating Jerky?

Yes, you can pause dehydrating jerky, but only under strict time and temperature limits or you risk bacterial growth that can make your food unsafe.

Jerky is a high-risk food compared to other dehydrated foods like fruits or vegetables. When you’re dehydrating meat, you’re working with animal protein that can harbor dangerous pathogens like Salmonella and E. coli. This makes pauses far riskier than when you’re drying tomatoes or potatoes.

Here’s the critical rule: any pause longer than about 1–2 hours at room temperature is unsafe. During a pause, meat should be kept at or below 40°F (4°C) or maintained above 130°F (54°C). Anything between those temperatures puts your jerky in the “danger zone” where bacteria multiply rapidly. The danger zone refers to temperatures between 40°F and 130°F, where bacteria can multiply rapidly (Fact 1). Pausing dehydration in this range, especially without proper cooling and storage, can lead to microbial growth and spoilage (Facts 2, 7). Gradual cooling and moisture assessment are important to prevent condensation and bacterial growth (Facts 3, 4, 6).

The safest approach—especially for beginners—is to plan your dehydration so it runs continuously until the jerky is completely dry. Think of it this way:

| Approach | Example | Safety Level |

|---|---|---|

| Continuous run | Start at 8 a.m., finish by 6 p.m. | Safest |

| Short pause with fridge | Stop at 10 p.m., refrigerate immediately, resume at 7 a.m. | Acceptable with precautions |

| Long room-temp pause | Turn off dehydrator at midnight, leave on counter until morning | Unsafe |

|

Understanding Jerky Dehydration and Food Safety

Drying jerky isn’t like making dried apples or herb mixes. You’re working with animal protein that starts out moist, warm, and perfect for pathogens if mishandled. Understanding why meat jerky requires extra care will help you make smarter decisions about pausing.

What Dehydration Actually Does

The dehydration process works by removing moisture from the meat—typically 85–95% of its original water content. When you reduce moisture to these levels, bacteria like Salmonella and E. coli can’t multiply easily. The result is a shelf-stable product that can last for weeks or months when stored properly.

However, there’s a catch. Most home food dehydrators operate at temperatures between 130–160°F (54–71°C). These temperatures are excellent for removing moisture but may not kill all bacteria on their own.

USDA Guidance in Plain Language

The USDA recommends that meat should reach 160°F (71°C) internally—and poultry should reach 165°F (74°C)—at least once during the jerky-making process. This can happen either:

- Before drying: Pre-cooking the meat in a marinade or the oven

- During drying: Using a dehydrator that reaches sufficient temperatures

- After drying: Finishing the jerky in a preheated oven

Why Pauses Are Particularly Dangerous

Here’s the problem with pausing: partially dried jerky has enough moisture remaining and a warm surface temperature that creates an ideal environment for rapid bacterial growth. If cooling is slow or pauses are long, you’re essentially giving pathogens a comfortable place to multiply.

Unlike sun drying methods used for centuries (which relied on salt, smoke, and specific climate conditions), modern home dehydration depends on consistent heat and air circulation. When you turn off that process, the safety mechanisms stop too.

When (and How Long) Can You Safely Pause Dehydrating Jerky?

Let’s get practical. You need to know exactly how long you can pause and under what conditions.

The 2-Hour Rule

The total time your raw or partially dried jerky spends in the “danger zone” (between 40°F/4°C and 130°F/54°C) should stay under 2 hours. This includes:

- Initial handling and preparation time

- Any pauses during dehydration

- Cooling time after the dehydrator stops

This 2-hour window is cumulative. If you spent 30 minutes preparing and loading your batch, you’ve already used up a quarter of your safe time.

Short Pauses (Under 30 Minutes)

Short, necessary pauses are generally fine. These include:

- Quickly rotating trays for even drying

- Moving the dehydrator to a different outlet

- Checking doneness on a few pieces

- Adding more strips to empty spots

During these brief interruptions, the meat stays hot and the pause is under 15–20 minutes. Just work quickly and get the dehydrator running again.

Longer Pauses (30 Minutes to 2 Hours)

These are risky territory. If you must pause for 30 minutes to an hour, keep the dehydrator door closed and don’t disturb the trays. The residual heat will keep the jerky warmer than room temperature for a while, buying you some time.

Extended Pauses (Over 2 Hours)

If you must pause for longer than about 1–2 hours, you need to rapidly chill the jerky to 40°F (4°C) or below. This means transferring it to the fridge or refrigerator, not leaving it on the counter. Room temperature pauses of several hours are unsafe and can allow pathogens to multiply to dangerous levels.

How to Pause Dehydrating Jerky Safely

When you need to pause, the method matters as much as the timing. Here’s how to do it right.

Pausing the dehydration process can create an ideal environment for microbial growth (Fact 1). To minimize risks, assess the moisture content before pausing (Fact 3), cool the food gradually to prevent condensation (Fact 4), and store partially dehydrated food properly (Fact 2). Improper cooling or storage can accelerate spoilage and bacterial growth (Facts 7, 6).

Before You Pause: Assess the Stage

Check where your jerky is in the drying process:

- Early stage (still soft, glossy, obviously raw-looking): Higher risk. Pause only if absolutely necessary.

- Mid-stage (leathery but still moist): Moderate risk. Proceed with caution.

- Near completion (firm, dry, cracking when bent): Lower risk, but still requires proper handling.

For Short Pauses (Under 30–60 Minutes)

- Leave jerky on the trays inside the dehydrator

- Keep the dehydrator door closed

- Don’t stack or cover the trays

- Restart as soon as possible

- Note the total pause time

For Longer Pauses (Overnight or Several Hours)

- Turn off the dehydrator

- Let trays cool briefly until just warm (not hot)

- Transfer jerky pieces to shallow containers or baking sheets

- Refrigerate uncovered or loosely covered so moisture doesn’t condense

- Do not seal in airtight containers while still warm—steam will create condensation

What NOT to Do

Never leave jerky in a powered-off dehydrator on the counter overnight. This is especially dangerous in warm kitchens (above 70°F/21°C) or humid environments. The meat will slowly cool through the entire danger zone, giving bacteria hours to multiply.

How to Resume Dehydrating Jerky After a Pause

You’ve paused safely. Now here’s how to get back on track.

Step 1: Inspect Before Resuming

Before doing anything else, visually inspect and smell the jerky:

- Discard immediately if you notice: Off odors, sliminess, visible mold, or unusual discoloration

- Acceptable signs: Normal meat smell, surface appears as expected, no sticky or tacky feel beyond normal

Step 2: Bring to Room Temperature

Return chilled jerky to room temperature briefly—about 10–15 minutes—while preheating your

Step 3: Arrange Properly

Spread pieces out in a single layer so no strips touch or overlap. This ensures even air circulation and a faster return to safe drying temperature. Overlapping pieces will trap moisture and dry unevenly.

Step 4: Verify Internal Temperature

Use a food thermometer on a test strip. Aim for the jerky to reach at least 160°F (71°C) internally at some point after resuming, especially if this temperature wasn’t achieved before the pause. This heat treatment is your safety net.

Alternative: Finish in the Oven

If your dehydrator isn’t available or you want extra assurance, you can finish jerky in the oven:

- Preheat oven to 170–200°F (77–93°C)

- Place strips on oven-safe racks over a baking sheet

- Dry until jerky reaches desired texture

- This provides both drying and heat treatment simultaneously

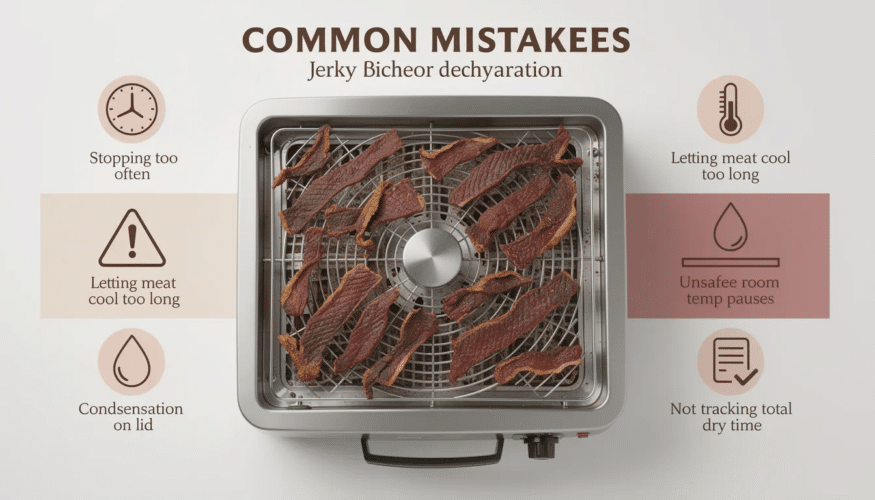

Common Mistakes When Pausing Jerky Dehydration

Avoid these errors that can turn your batch from safe to risky:

- The Overnight Counter Mistake

Turning off the dehydrator at midnight and leaving partially dried jerky inside on the counter until morning is one of the most dangerous practices. This is particularly risky in summer or in humid climates where bacteria thrive. - The Steam Trap

Covering hot jerky tightly with plastic wrap or putting it into deep, lidded containers while still warm creates a steam trap. The condensation re-hydrates the surface—perfect conditions for bacteria and mold growth. Always let jerky cool and use shallow, open containers. - The On-Off Cycle

Repeatedly cycling meat between warm and cool—on for a few hours, off for a few hours at room temp, repeated—is especially dangerous. Each cycle through the danger zone compounds the risk. If you can’t commit to continuous processing, don’t start the batch. - The Smell Test Fallacy

Relying on “smell” alone to judge safety is unreliable. Many dangerous bacteria do not cause obvious odors in early stages. By the time jerky smells off, it may have been unsafe for hours. Trust temperature and time, not your nose. - Ignoring Humidity

Your local humidity affects how quickly paused jerky absorbs moisture from the air. Someone in Arizona faces less risk than someone in Florida during the same pause duration. Be aware of your environment and adjust accordingly.

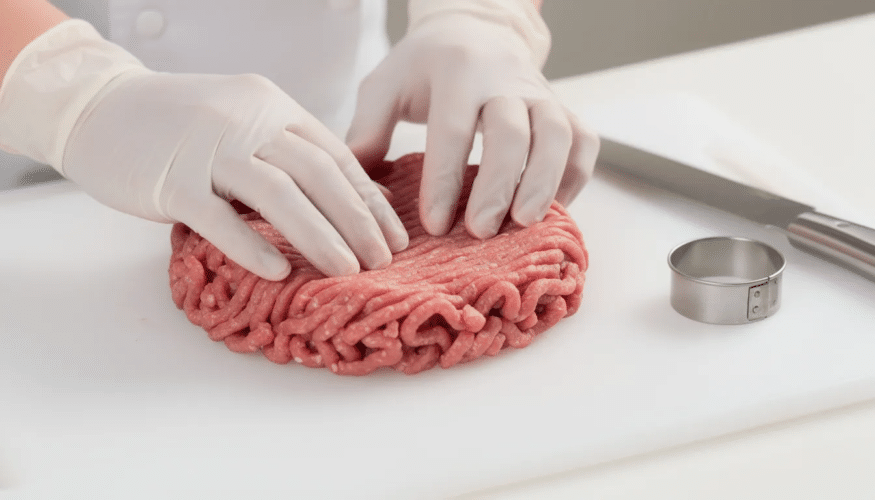

Special Considerations: Ground Meat Jerky vs. Whole Muscle Jerky

Not all jerky carries the same risk profile. Understanding the difference between ground and whole muscle preparations can help you make better decisions about pausing.

Ground Meat Jerky: Higher Risk

Ground beef or venison jerky (extruded strips from a jerky gun) presents elevated food safety concerns:

- Bacteria get mixed throughout the meat during grinding, not just on the surface

- The interior of each strip must reach 160°F (71°C) for safety

- There’s no “searing the outside” effect that helps with whole cuts

Recommendation: If you’re making ground meat jerky, avoid pausing the dehydration process entirely unless you can immediately chill the jerky in a refrigerator. The risk simply isn’t worth it.

Whole Muscle Jerky: Still Requires Caution

Whole muscle jerky (sliced from roasts or steaks) carries surface bacteria, but the risk profile is somewhat lower since pathogens are primarily on the exterior. However, long pauses are still not advised, and all the same temperature rules apply.

The Role of Curing Salts

Using curing salts (such as Prague Powder #1) and a salty, teriyaki, or other high-salt marinade can reduce—but not eliminate—the risk during any pause. Salt inhibits bacterial growth but doesn’t replace proper temperature control. Think of curing salts as an additional safety layer, not a substitute for safe handling.

Sugar in marinades provides flavor but offers minimal preservation benefit compared to salt. A well-prepared marinade helps, but it won’t save a batch that’s been left in the danger zone for hours.

Planning Your Jerky Dehydration to Avoid Pauses

The best way to handle pauses is to not need them in the first place. With a bit of planning, you can run most batches straight through.

Start Early

Begin your jerky batch early in the day. Loading the dehydrator between 7–9 a.m. works well because most batches take 6–10 hours depending on:

- Meat thickness

- Dehydrator temperature

- Ambient humidity

- Whether meat was marinated or pre-cooked

An 8 a.m. start typically means finished jerky by early evening—no overnight pause required.

Slice Consistently

Cut your meat to a consistent thickness, around 1/8 to 1/4 inch. This makes drying times more predictable and less likely to run unexpectedly late into the night. Inconsistent thickness means some pieces finish hours before others.

| Thickness | Approximate Drying Time |

|---|---|

| 1/8 inch | 4–6 hours |

| 1/4 inch | 6–10 hours |

| 3/8 inch | 10–14+ hours |

Batch Size Matters

A half batch dries faster than a full batch. If you’re worried about timing, prepare a smaller quantity that you’re confident will finish during your available window.

Have a Backup Plan

If a schedule conflict comes up unexpectedly, rapid refrigeration of partially dried strips is safer than gambling on a long, warm pause. Keep shallow containers ready in case you need to transfer jerky to the fridge quickly.

Use a Timer

Set a timer to remind yourself to check on the batch. This prevents the “I forgot it was running” scenario that leads to over-dried or neglected jerky.

How to Tell When Jerky Is Fully Done (So You Don’t Need to Pause)

Confidently recognizing finished jerky helps you avoid unnecessary pauses and repeated heating cycles. Here’s how to know when you’re truly done.

The Bend Test

The classic doneness test: properly dried jerky should be:

- Firm and dry to the touch

- Bendable but not brittle

- When bent, it should crack slightly but not snap cleanly in half

If it bends like rubber without cracking, it needs more time. If it snaps like a cracker, it may be over-dried (still safe, just tough).

The Cut Test

Cut a strip open and examine the interior:

- Should look uniformly colored throughout

- No visible red or pink juices

- No raw or wet appearance in the center

- The interior should look like the surface, just lighter in color

The Cool-Down Test

Here’s a trick many beginners miss: cool a test piece completely before judging dryness. Warm jerky often feels moister and more flexible than it truly is. Let a piece sit at room temperature for 10–15 minutes, then test again.

Document Your Process

Keep a simple notebook with your drying times, temperatures, meat thicknesses, and results. After a few batches, you’ll know exactly how long your specific setup takes. This knowledge lets you plan batches that finish without interruption, every time.

Note details like:

- Meat type and cut

- Marinade used

- Slice thickness

- Dehydrator temperature

- Total drying time

- Final texture and flavor notes

FAQs About Pausing Jerky Dehydration

Can I turn off the dehydrator while I run errands?

For a short trip (under an hour), leaving the unit running is actually safer than turning it off. The continuous heat and air circulation maintain safe conditions. Turning it off for several hours while you’re gone puts the jerky in the danger zone.

Is it okay to pause jerky overnight in the fridge and restart in the morning?

Yes, this can be done safely if:

- Jerky is chilled quickly (within 2 hours of turning off the dehydrator)

- It’s stored uncovered or loosely covered in shallow containers

- You reheat to safe temperature when drying resumes

- Total danger zone time stays under 2 hours

What if I accidentally left my dehydrator off for several hours?

This is a judgment call, but err on the side of caution. If the meat was in the danger zone (room temp, 40–130°F) for more than about 2 hours—especially if it was still moist—discard the batch. The risk of foodborne illness isn’t worth saving a few dollars of meat.

Can I finish jerky in the oven instead of restarting the dehydrator?

Absolutely. Place strips on wire racks over a baking sheet in a low oven (around 170–200°F / 77–93°C). This works particularly well after a refrigerator pause because you get both cooking and drying simultaneously, ensuring the meat reaches safe internal temperatures.

How do I know if paused jerky has spoiled?

Look for these warning signs:

- Slimy or tacky surface texture

- Off odors (sour, ammonia-like, or just “wrong”)

- Visible mold (any color)

- Unusual discoloration

When in doubt, throw it out. No batch of jerky is worth a foodborne illness.

Conclusion: Best Practices for Safe Jerky Dehydration Pauses

Continuous dehydration from start to finish is the gold standard for making jerky safely. However, with proper precautions, short and well-managed pauses—including overnight refrigeration—can be accomplished without sacrificing food safety or quality.

Remember the core rule: keep total time in the 40–130°F (4–54°C) danger zone under about 2 hours for raw or partially dried meat. When you must pause, chill rapidly. When you resume, heat thoroughly. And always trust temperature and time over smell or appearance.

With good planning, attention to temperature control, and the techniques covered in this post, your home-dried beef jerky can be both safe and delicious. Start your next batch early in the day, maintain consistent slice thickness, and enjoy the peace of mind that comes with running your dehydrator straight through to a perfect, shelf-stable finish.