A Beginner’s Guide to Choosing the Best Industrial Food Dehydrator for Your Business

Industrial food dehydrators are essential equipment in the world of food processing, and this guide is for food manufacturers, commercial kitchens, and anyone considering industrial-scale food dehydration. Choosing the right industrial

Industrial food dehydrators can be used for a variety of applications, including drying fruits, vegetables, meats, and herbs. These high-capacity machines are specifically engineered for commercial dehydration and commercial food drying, with advanced features and results for businesses that need to process significant volumes.

- Benefits of Industrial Dehydrators

- Types of Industrial Food Dehydrators

- What to Look For

- Energy Efficiency in Dehydration

- Product Specific Dehydrator

- Commercial Food Dehydrator Considerations

- Buying the Right One for Your Business

- Industrial Dehydrator Models and Brands

- Maintenance and Troubleshooting

- Case Studies and Success Stories

- Summary

Benefits of Industrial Dehydrators

Industrial dehydrators bring a host of advantages to commercial food production, making them indispensable for businesses aiming to scale up their operations efficiently.

Consistent Results

By utilizing a commercial

Thanks to their innovative design, industrial dehydrators deliver consistent results batch after batch, ensuring that every product meets strict quality standards.

Energy Efficiency

Their energy-efficient operation means businesses can maximize output without excessive energy consumption, supporting both profitability and sustainability. Modern industrial food dehydrators can achieve energy savings of 35-45% due to patented power-throttling technology.

Versatility

Whether you’re producing dried vegetables, fruits, or specialty products, these machines enhance efficiency, streamline the production process, and help preserve the nutritional content of your food. For any commercial food operation, investing in a high-quality dehydrator is a smart move that delivers long-term benefits in product quality, efficiency, and reduced waste.

Transition: Now that we’ve covered the benefits, let’s look at the different types of industrial food dehydrators and their key features.

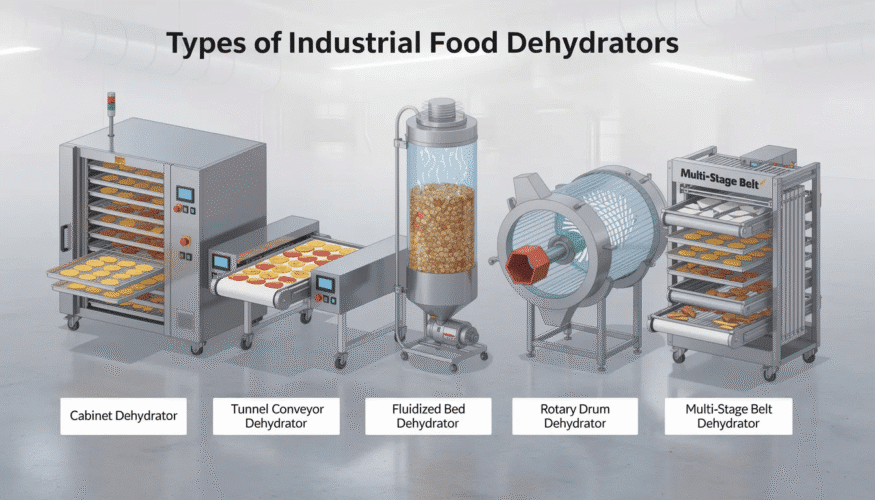

Types of Industrial Food Dehydrators

When choosing an industrial food dehydrator, you need to understand the different types and what they offer. Generally, these machines can be classified into batch, continuous, and hybrid models. They can also be classified by power source, electric or gas-powered. Tray size is important for handling large batches, and the door design allows for easy loading and unloading of food items. Maintaining the surface of the dehydrator is also crucial for hygiene and machine longevity.

Comparison Table: Batch, Continuous, and Hybrid Dehydrators

| Type | Key Features | Best Use Cases |

|---|---|---|

| Batch | Food loaded onto trays for set drying cycle; simple operation; easy to use | Small to medium-sized businesses; non-continuous ops |

| Continuous | Conveyor belts move food through drying zones; allows continuous loading | Large-scale operations; high throughput needed |

| Hybrid | Switches between batch and continuous modes; versatile control options | Businesses needing flexibility and versatility |

Electric vs Gas-Powered Dehydrator

Industrial food dehydrator can also be classified by power source. Electric dehydrators are more popular because of their ease of installation and operation. They offer precise temperature control and are generally more energy efficient. Gas-powered dehydrators are preferred where electricity is expensive or where natural gas is available. They heat up faster and can be more cost-effective in the long run.

Advanced Technologies

A modern industrial food dehydrator comes with advanced technologies to improve performance and efficiency. A versatile control panel allows users to set the temperature and select different drying options, such as a fan-only drying mode for drying products without heat. For example, some models have ambient air mode which uses natural air to assist in the drying process, reducing energy consumption. Intake and exhaust valves are also built into these machines to improve airflow and temperature control for optimal drying conditions.

Transition: Understanding the types and technologies available is crucial, but knowing what features to look for will help you make the best choice for your business.

What to Look For

When choosing an industrial food dehydrator, consider the following features to make sure it meets your business needs:

- Drying area and capacity: The drying area and tray area of an industrial food dehydrator are key factors that will affect how much food it can handle. A bigger drying area means more food can be processed at one time, increasing efficiency and throughput. When choosing one, consider the size and shape of the trays and shelves and the spacing between them. A well-designed layout will make the most of the space and ensure even drying. Also, look for features like a stainless steel drip tray which makes cleaning and maintenance easy. High-capacity dehydrators are needed for businesses that need to process large volumes of food regularly.

- Temperature control and range: Temperature control is key to achieving optimal drying results. These appliances have advanced temperature control systems that can be adjusted precisely. A wide temperature range is good as it gives you the flexibility to dry different types of food products. Make sure the dehydrator can maintain a consistent temperature throughout the drying process. Some models have multiple temperature zones so you can dry different products at the same time. This is useful for businesses that process different types of food products.

- Airflow and circulation systems: Airflow and circulation systems are key components of industrial

food dehydrator . These systems ensure heat is distributed evenly throughout the drying area to prevent uneven drying and spoilage. Look for products with powerful airflow systems and advanced circulation features. Advanced airflow systems like intake and exhaust valves can improve the drying process by improving air distribution and temperature control. These features will maintain optimal drying conditions for consistent and high-quality results. - Product-specific capabilities: Some dehydrators are designed with special features to cater to specific types of food and will perform and be more efficient for those applications.

- Included accessories: Check for included accessories such as installation parts and user manuals to ensure a complete and convenient setup.

Transition: Next, let’s explore how energy efficiency plays a role in industrial food dehydration.

Energy Efficiency in Dehydration

Energy efficiency is a top priority in modern food processing, and commercial food dehydrators are engineered to optimize the drying process while minimizing energy use.

Advanced Energy-Saving Features

Advanced technologies in these units ensure that heat and airflow are precisely controlled, reducing unnecessary energy consumption and keeping operational costs in check. By streamlining the dehydration process, businesses can achieve high-volume production without sacrificing efficiency or increasing their carbon footprint.

Eco-Friendly Design

Many commercial dehydrators are built with eco-friendly features, such as recyclable materials and systems that use minimal water, making them a responsible choice for businesses focused on sustainability.

Cost Savings

Efficient operation not only lowers utility bills but also helps reduce overall waste, supporting both environmental and financial goals. For companies looking to enhance their production capabilities while maintaining a commitment to energy efficiency, investing in a modern commercial

Transition: With a clear understanding of energy efficiency, it’s important to consider how different dehydrators are tailored for specific products and industries.

Product Specific Dehydrator

While a general-purpose industrial dehydrator is versatile and can handle a wide range of products, some businesses may need product-specific dehydrating appliances. These machines are designed with special features to cater to specific types of food and will perform and be more efficient. Spices are another category that benefits from specialized dehydration equipment, as these machines help preserve the flavor and aroma essential for high-quality spice products.

Fruits and Vegetables

Fruits and vegetables require specific drying conditions to preserve their flavor, color, and nutritional value. Dehydrators for these products have specialized trays and shelves to prevent sticking and ensure even drying. Advanced temperature control systems help preserve the delicate nature of fruits and vegetables during the drying process. Industrial food dehydrators are designed to maintain natural vitamins and minerals, preserving nutrients, and offer a nutrient-dense preservation method compared to high-heat approaches.

Dehydrator for Meats

Commercial dehydrators are designed to handle the challenges of drying meat products like jerky. These machines have robust construction and powerful airflow to manage the high moisture content of meats. Specialized racks and shelves are designed to support meat strips for uniform drying and to prevent spoilage.

Dehydrator for Herbs

Herbs need gentle drying to retain their essential oils and flavors. Herb-specific dehydrators have adjustable temperature settings and low-temperature drying options to cater to the delicate nature of these products. Fine mesh trays are used to prevent smaller herbs from falling through during the drying process.

Pet Treats and Food Production

The pet food industry has seen rapid growth, and commercial dehydrators are at the heart of producing high-quality pet treats and food. Using a

Commercial dehydrators allow pet food producers to operate at scale, delivering bulk quantities of consistent, high-quality treats. With precise control over temperature, airflow, and drying cycles, manufacturers can ensure that every batch meets strict safety and quality standards. This level of control is essential for maintaining the nutritional integrity of pet food and treats, helping businesses stand out in a competitive industry while meeting the evolving demands of their customers.

Dried Fruit Production

Dried fruit production is a major application for commercial food dehydrators, enabling businesses to process large quantities of fruit efficiently. By leveraging the dehydration process, manufacturers can preserve fruits like apricots, apples, and mangoes, significantly extending their shelf life and reducing reliance on refrigeration. This not only helps maintain the quality and flavor of the fruit but also makes storage and transportation more convenient.

Commercial dehydrators are equipped with advanced temperature control systems and precision airflow, ensuring that each batch of dried fruit is evenly processed for optimal texture and taste. These systems are designed to handle high-volume production, making them essential for businesses that need to deliver consistent, high-quality dried fruit products to the market. With the ability to preserve and process fruit efficiently, commercial dehydrators help businesses meet consumer demand while maintaining product excellence.

Industry Specific Dehydrator

Some industries like the meat or dairy industry have specific requirements for food dehydration. Industry-specific dehydrators are designed to meet these needs with features like advanced temperature control, specialized trays and racks, and robust construction to handle the unique challenges of these industries. Additionally, some industry-specific dehydrators are designed to support packaging requirements for food, pet food, fibers, and pharmaceuticals, ensuring product quality and stability.

Transition: After understanding product-specific options, let’s review key considerations for commercial food dehydrators.

Commercial Food Dehydrator Considerations

Commercial food dehydrator are for heavy-duty use in commercial settings, high-capacity drying, and advanced features for best results. When buying a commercial food dehydrator consider:

Choosing the right commercial

Size and Capacity

Size and capacity are a big consideration for commercial operations. Make sure the dehydrator can handle the volume of food your business processes daily. A larger dehydrator with high-capacity drying areas are ideal for businesses that need large-scale food dehydration.

Temperature Control and Airflow Systems

Advanced temperature control and airflow systems are key to consistent and high-quality drying results. Look for a dehydrator with precise temperature control, multiple temperature zones, and powerful airflow systems. These features will ensure food is dried evenly and efficiently and retain its quality and flavor.

Stainless Steel Construction and Durability

A commercial food dehydrator should be built to withstand heavy-duty use. Stainless steel construction is common in high-end dehydrator, durable, easy to clean, and corrosion resistant. Food-grade 304 stainless steel is required for contact surfaces to resist corrosion and ensure hygiene. Make sure it is robust and built to last, minimizing downtime and maintenance costs.

Advanced Features

Look for a commercial dehydrator with features like intake and exhaust valves, ambient air mode, and automatic cleaning system. These advanced features help prevent premature food spoilage by regulating humidity and airflow, ensuring even drying and maintaining product quality. These features will enhance the performance and efficiency of the appliance, better drying results, and lower operational costs. Additionally, consider the shipping cost when purchasing these, as some models offer competitive shipping options or free shipping on orders above a certain amount.

Transition: With these considerations in mind, let’s discuss how to choose the right industrial

Buying the Right One for Your Business

Choosing the right industrial food dehydrator for your business involves considering several factors, the specific needs of your operation, the type and quantity of products you will be dehydrating, and the features that matter most to you. Choosing the right industrial

Specific Needs of Your Business

Every business has unique requirements for food dehydration. Consider the type of products you will be drying, the volume of food you need to process, and the specific drying conditions required for your products. This will help you filter down your options and choose the right dehydrator for you.

Features and Capabilities

Evaluate the features and capabilities of different dehydrating appliances, and focus on the ones that matter most to your business. Key features to consider are drying area and capacity, temperature control and range, airflow and circulation systems, and product specific capabilities. Some industrial food dehydrators also offer the ability to save and replicate recipes, providing convenience and consistency for businesses. Make sure the one you choose has the features you need to achieve the best drying results.

Maintenance and Troubleshooting

Maintenance and troubleshooting is a big consideration when buying an industrial food dehydrator. Wearing food safety gloves during maintenance is essential to ensure safe and hygienic operation. Look for machines that are easy to clean and maintain, with features like stainless steel drip trays and an automatic cleaning system. Also, consider the technical support and troubleshooting resources available so any issues can be resolved quickly and efficiently. A reliable support and service team can further enhance the experience of using an industrial

Transition: Once you’ve selected the right dehydrator, it’s helpful to know which brands and models are most reputable in the industry.

Industrial Dehydrator Models and Brands

There are many industrial dehydrator models and brands out there, each with its own features and benefits. When buying it, consider the reputation and reliability of the manufacturer and the warranty and support they offer.

Brands

Some of the popular brands are Excalibur and Commercial Dehydrators America. These brands are known for their high-quality construction, advanced features, and reliable performance. Research different manufacturers and read reviews to find the right dehydrator for you.

Unique Features and Benefits

Different models have unique features and benefits. In addition to these features, certain models offer the advantage of inexpensive international shipping rates, making them more accessible globally. For example, some models have advanced temperature control systems, others have specialized trays and racks for specific products. Consider your business needs and choose a model that fits those requirements. Here are some to look out for:

- Advanced Temperature Control: Some models have highly precise temperature control systems where you can set and maintain the exact temperature needed for best drying. This is very useful for businesses that dry different types of products, each requiring different drying conditions.

- Specialized Trays and Racks: Depending on the food being dehydrated, specialized trays and racks can boost efficiency and product quality.

Transition: To keep your dehydrator running smoothly, regular maintenance and troubleshooting are essential.

Maintenance and Troubleshooting

Maintenance is key to optimal performance and longevity. A maintained dehydrator not only runs more efficiently but also produces better-quality dried products. Here’s some maintenance and troubleshooting tips to keep your appliance in good shape:

Cleaning and Maintenance

- Cleaning: Clean the trays, racks, and interior surfaces of the dehydrator regularly to prevent food residue buildup and maintain hygiene.

Troubleshooting Common Problems

- Inconsistent Drying: If the food is not drying evenly, check the airflow systems and make sure the trays are not overloaded. Overloading can block airflow and cause inconsistent drying.

- Temperature Fluctuations: If the dehydrator can’t maintain temperature, check the thermostat and heating element. Replace any faulty parts to restore temperature control.

- Unusual Noise: Unusual noise may be due to faulty fans or moving parts. Lubricate or replace the affected parts to fix the problem.

- Poor Airflow: If the airflow is weak, clean the intake and exhaust vents and check the fans for any blockage. Make sure it is placed in a well-ventilated area to promote good airflow.

- Electrical Issues: If the appliance won’t turn on or has electrical problems, check the power supply and connections. If the problem persists, consult a professional technician.

By following these maintenance and troubleshooting tips you’ll be able to keep your appliance in good shape and produce high-quality dried products.

Transition: Seeing real-world examples can help you understand the impact of industrial dehydrators on business operations.

Case Studies and Success Stories

Many businesses have transformed their operations by integrating commercial dehydrators into their production lines. For instance, a leading pet food manufacturer boosted its production capacity by 30% after adopting a commercial dehydrator, enabling the company to produce nutritious pet treats in bulk while cutting down on energy use and waste. This not only improved product quality but also enhanced operational efficiency.

In another example, a fruit processing company reduced its shipping cost by 25% by switching to dried fruit products. The lighter weight and longer shelf life of dried fruit made transportation more cost-effective, resulting in significant savings. These real-world success stories highlight the tangible benefits of commercial dehydrators across different industries—from pet food to dried fruit production. By investing in a commercial dehydrator, businesses can achieve greater efficiency, reduce costs, and deliver high-quality products to their customers, all while minimizing waste and maximizing production output.

Transition: To wrap up, let’s summarize the key points to help you make an informed decision.

Summary

Choosing the right industrial dehydrator for your business can be tricky but by considering the points above you’ll be better equipped to make a decision. Remember to consider your business needs, what products you will be dehydrating, and how much, and look for one that can deliver the features and performance you need for optimal drying.

Look for the manufacturer’s reputation warranty and support to ensure you’re buying a quality and durable product. Maintenance and troubleshooting are key to maintaining your dehydrator’s performance and longevity so make sure you follow the guidelines.

With the right food dehydrating product you can dry efficiently and consistently, reduce waste, and improve product quality and shelf life. This investment will take your business to the next level and give you the tools to succeed in the food processing industry.