Freeze Dried Fruit Supplier

Choosing the right freeze dried fruit supplier can make or break your product line. This guide is intended for food manufacturers, product developers, and commercial buyers seeking reliable freeze dried fruit suppliers. Whether you’re launching a new snack brand, reformulating a cereal, or sourcing ingredients for a commercial kitchen, your supplier determines the quality, consistency, and reliability of every batch. Selecting the right supplier is crucial for ensuring product quality, food safety, and business success in the competitive food industry. This article focuses on top freeze dried fruit suppliers and what separates the best from the rest.

The freeze dried fruit market has exploded in recent years, driven by consumer demand for healthy, convenient snacks with clean ingredient lists. Retail snack brands use freeze dried strawberries and blueberries for kid-friendly lunchbox packs. Cereal and granola producers rely on deliciously crunchy fruit pieces that stay crisp until they hit the milk. Bakeries incorporate real fruit into muffins, pies, and desserts without the moisture issues of fresh fruit.

Meal kit companies and emergency food suppliers depend on freeze dried fruit for its remarkable shelf life—often 18 to 25 years when properly packaged with no preservatives or additives. The process locks in intense flavor and high nutritional value that conventional dried fruit simply cannot match. For food manufacturers, working with a quality freeze dried fruit supplier means fewer supply disruptions, better taste in the final product, and happier customers.

- What Is Freeze Dried Fruit and How Is It Made?

- Key Benefits of Working With a Top Freeze Dried Fruit Supplier

- Product Range: Popular Freeze Dried Fruits and Formats

- Quality Standards and Certifications to Expect

- Packaging Options: Retail, Foodservice, and Industrial

- Freeze Dried Fruit for Different Industries and Applications

- How to Evaluate and Choose the Right Freeze Dried Fruit Supplier

- Trends in the Freeze Dried Fruit Market in 2024

- Working With a Top Freeze Dried Fruit Supplier: Next Steps

What Is Freeze Dried Fruit and How Is It Made?

Freeze drying, technically called lyophilization, removes water from frozen fruit under vacuum conditions. Unlike conventional air dried methods that use heat, freeze drying preserves the fruit’s cellular structure, color, and nutritional content. The freeze-drying process allows for the preservation of flavor, color, shape, and nutritional value of the fruit. The cell structure of the fruit remains intact during the freeze-drying process. The result is a lightweight, crispy product that tastes remarkably close to fresh fruit.

The process follows a precise sequence. Suppliers start by selecting ripe fruit at peak freshness, then wash and cut it into the desired form—whole berries, slices, or dices. The fruit undergoes rapid freezing at temperatures around –40°C. Once frozen solid, it moves into a vacuum chamber where the magic happens: sublimation. Ice transforms directly into vapor without passing through a liquid phase, leaving behind a porous, crunchy texture.

Compared to air drying, freeze drying operates at much lower temperatures and causes significantly less nutrient loss. Air dried fruit can lose up to 50% of heat-sensitive compounds like vitamin C and antioxidants. Properly freeze dried fruit retains 90–97% of original vitamins, natural flavor, and pure fruit goodness. There’s no need for added sugar or sulfites to maintain sweetness or color—the fruit speaks for itself.

Key Benefits of Working With a Top Freeze Dried Fruit Supplier

Businesses choose leading suppliers for three core reasons: quality consistency across batches, food safety certifications that satisfy retail buyers, and flexible product formats that fit different applications. Many suppliers offer bulk freeze-dried fruit without added sugar or preservatives.

Here are the main advantages of sourcing from a top supplier:

| Benefit | Explanation |

|---|---|

| Long shelf life | Typically 12–24 months for retail, up to 25 years for emergency food |

| Reduced waste | Compared to fresh fruit, which spoils quickly |

| Easy storage and transport | Due to 90% weight reduction |

| No hassle with refrigeration | No need for cold chain logistics |

| Clean ingredient lists | No added sugar, no sulfites, and no artificial preservatives |

The economics are compelling. Bulk freeze dried fruit can replace multiple times its weight in fresh fruit. One pound of freeze dried berries equals approximately 7–8 pounds of fresh berries, saving massive storage space and transport cost. For a commercial kitchen processing hundreds of recipes per day, this difference translates directly to money saved.

Applications span nearly every food category: snack packs, cereals, bakery fillings, ice cream inclusions, smoothies, yogurt toppings, and outdoor or emergency food kits. Kids love the sweet, intense fruit flavor. Adults appreciate the nutritional content without the guilt. Yum.

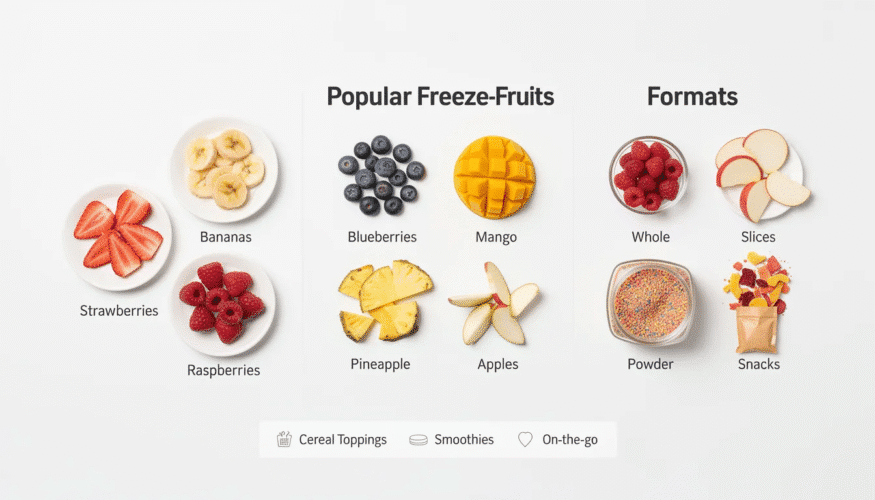

Product Range: Popular Freeze Dried Fruits and Formats

Top suppliers carry an extensive spectrum of fruits, blends, and value-added formats to meet diverse customer needs. Look for suppliers that offer a wide array of freeze-dried fruits, including common and exotic options. The best freeze dried fruit supplier doesn’t just stock a few options—they offer everything from whole berries to fine powders.

Popular single-fruit options include:

| Fruit | Common Forms | Primary Applications |

|---|---|---|

| Strawberries | Whole, slices, dices, powder | Cereals, snacks, baking |

| Blueberries | Whole, crumbles | Granola, muffins, smoothies |

| Raspberries | Whole, pieces | Chocolate, desserts, beverages |

| Apples | Slices, dices, rings | Snacks, cereal, baby food |

| Bananas | Slices, chips | Snacks, trail mix, cereal |

| Mango | Dices, slices | Tropical blends, smoothies |

| Pineapple | Chunks, rings | Snack mixes, candy, baking |

| Cherries | Whole, halves | Confectionery, cereals |

| Mixed blends have become increasingly popular. Berry medleys (strawberry-blueberry-raspberry) sell well in the snack aisle. Tropical mixes featuring pineapple, mango, and bananas appeal to adventurous consumers. Orchard blends combine freeze dried apples with pear and peach for a familiar, comforting flavor profile. |

Different cut styles serve different purposes. Whole berries work perfectly for retail snack pouches and cereal inclusions. Slices and rings make eye-catching toppings for desserts. Dices and cubes integrate seamlessly into baking applications. Crumbs and granules suit inclusions in chocolate and candy. Fine fruit powders—increasingly popular in 2024—provide natural color and nutrition for smoothie brands, sports nutrition products, and bakery manufacturers seeking clean-label solutions.

Quality Standards and Certifications to Expect

Top freeze dried fruit suppliers invest heavily in food safety infrastructure and quality management systems. When evaluating a potential supplier, certifications tell you whether they meet the standards your retail partners and food safety auditors expect.

Essential certifications to look for:

- GFSI-recognized schemes: BRCGS, FSSC 22000, or SQF

- HACCP plans: Documented and audited regularly

- ISO 22000 certification: Where applicable

- Organic certifications: (USDA Organic, EU Organic) for organic product lines

- Kosher and Halal certifications: For specific market requirements

Beyond certifications, robust allergen control programs matter. Your supplier should maintain traceability from farm to finished product and provide documented pesticide residue and heavy metal testing for every lot. Labeling should be crystal clear: 100% fruit, no added sugar, no sulfites, with origin indication (strawberries from Poland, dried blueberries from Chile, mango from Peru).

Reputable suppliers provide certificates of analysis (COAs), microbiological test results, and stable moisture and water activity targets for each batch. If a supplier hesitates to share these documents, consider it a red flag.

Packaging Options: Retail, Foodservice, and Industrial

Leading suppliers tailor packaging to different customer segments. What works for a family buying snacks at the grocery store differs dramatically from what a food manufacturer needs for production lines.

Retail packaging typically features resealable foil or high-barrier pouches with moisture and oxygen absorbers. Pack sizes range from 20g to 100g, with eye-catching graphics and prominent “no added sugar” claims that health-conscious consumers scan for in the snack aisle. The package must maintain freshness and that signature crunch.

Foodservice options serve cafés, bakeries, and small manufacturers. These typically come in 500g to 2.5kg bags—convenient for daily use in a commercial kitchen without the bulk of industrial quantities. Resealable closures help maintain quality between uses.

Industrial and bulk packaging scales up to 5kg, 10kg, or 20–25kg cartons or poly-lined bags. Large-scale production lines and co-packers need these volumes to maintain efficient operations. Some suppliers offer custom container sizes to match specific production requirements.

Regardless of format, good packaging protects against moisture and light, maintains crisp texture throughout the stated shelf life, and clearly shows production date and best-before date (typically 18–24 months after production). Stock rotation becomes simple when dating is prominent.

Freeze Dried Fruit for Different Industries and Applications

Top suppliers design product lines with different industries in mind. Understanding where and how the fruit will be used helps them recommend the right form, cut size, and packaging.

Retail snack brands represent a massive category. Single-serve pouches packed with freeze dried fruit fit perfectly in kids’ lunchboxes. Mixed fruit snack bags target adults seeking healthy on-the-go options. Hikers and travelers appreciate lightweight, nutrient-dense packs that rehydrate in the mouth for a burst of sweet flavor.

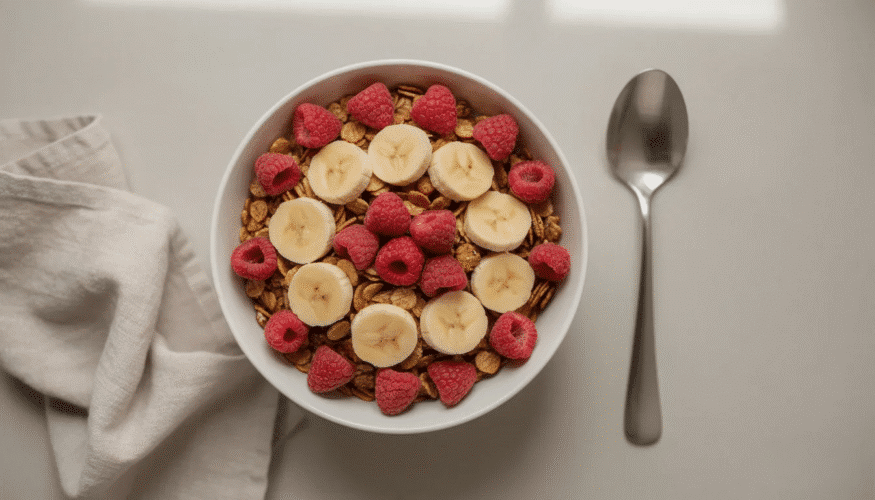

Cereal and granola producers need small dices and slices that stay crispy in the package but soften slightly when mixed with milk or yogurt. Berries are particularly popular here—those little pops of color make the bowl look delicious and justify premium price positioning.

Bakery and confectionery applications demand consistent piece sizes and intense flavor. Freeze dried raspberry powder creates stunning pink buttercream. Strawberry pieces add pops of real fruit to chocolate bars. Blueberry crumbles mix into muffin batter without bleeding like fresh or conventional dried fruit would.

Specialty sectors include smoothie bars using fruit powders for natural color and vitamins, hotel buffets offering premium breakfast toppings, airlines serving lightweight snacks, and emergency food manufacturers requiring ingredients with multi-decade shelf life. Each sector has unique specifications, and the best suppliers understand these nuances.

How to Evaluate and Choose the Right Freeze Dried Fruit Supplier

Choosing a freeze dried fruit supplier requires due diligence across multiple dimensions: product quality, production capacity, customer service responsiveness, and competitive price points all factor into the decision.

Sourcing and Origin Networks

Start by examining the supplier’s origin networks. Where do they source their fruit? Can they provide year-round availability for core fruits like strawberries, freeze dried apples, and bananas? Seasonal crop variations affect supply, and the best suppliers maintain relationships with growers across multiple countries and hemispheres to ensure continuity.

Product Sampling and Testing

Request product samples before signing any contract. Check taste, texture, color vibrancy, and how the fruit performs when incorporated into your actual recipe. Does it hold up during baking? Does it rehydrate properly in your smoothie formulation? Reviews from other customers help, but nothing beats testing in your own production environment.

Commercial Terms

Evaluate commercial terms carefully:

- Minimum order quantities (MOQs) and whether they fit your volume needs

- Lead times for standard orders and ability to handle urgent requests

- Logistics options: domestic stock versus direct import

- Payment terms and pricing transparency

Support Services

Finally, assess support services. Does the supplier offer dedicated account managers? Can their technical team help with formulation challenges? Do they provide private label capabilities if you want your own brand on the container? Transparent communication—especially when crop issues arise—separates great suppliers from merely adequate ones.

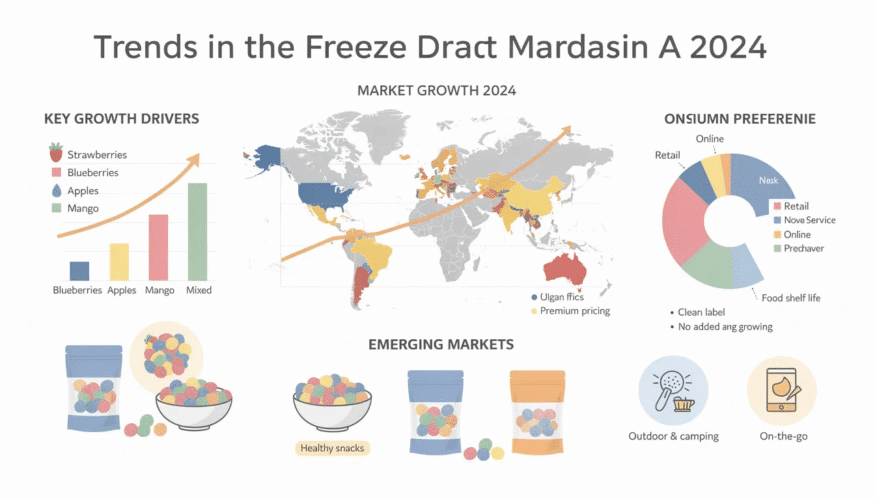

Trends in the Freeze Dried Fruit Market in 2024

The freeze dried fruit market continues strong growth, driven by healthy snacking habits and clean-label preferences that show no signs of slowing. The global market reached USD 35.7 billion in 2023 and is projected to hit USD 55.21 billion by 2030.

Organic and Additive-Free Demand

Key trends shaping supplier strategies in 2024:

- Rising demand for organic freeze dried fruit, particularly in North America and Europe

- Sugar-free and additive-free snacks targeting health-obsessed consumers

- Kid-friendly formats that parents feel good about packing

- Functional products like smoothie bowls and breakfast kits using fruit powders for natural color and nutrition

- Direct-to-consumer e-commerce channels creating new distribution opportunities

Sustainability Initiatives

Sustainability expectations are reshaping the industry. Suppliers are investing in recyclable or compostable packaging to reduce environmental impact. Some process cosmetically imperfect fruit—produce that would otherwise go to waste—into high-value freeze dried products, addressing food waste concerns while maintaining quality.

Innovation and Flexibility

Brands increasingly use freeze dried fruit for limited-edition flavors and seasonal launches. The convenience of long shelf life means you can develop a recipe months in advance without worrying about ingredient spoilage. This flexibility gives product developers room to create innovative combinations and kick off campaigns with confidence.

Working With a Top Freeze Dried Fruit Supplier: Next Steps

Partnering with a top-tier freeze dried fruit supplier supports consistent product quality, reliable supply chains, and ongoing new product innovation. The right supplier becomes a strategic partner, not just a vendor filling orders. In a market growing at 6–9% annually, securing strong supplier relationships now positions your brand for long-term success.

Before reaching out to suppliers, define your needs clearly. Document the fruit types you require, preferred formats (whole, slices, powder), estimated volumes per month, and target markets (retail, foodservice, industrial). Be specific about quality requirements—organic only, particular origin countries, or specific certifications your retail partners demand.

Prepare a short brief that includes preferred certifications, packaging formats, and any allergen constraints. If you’re developing products for the natural or organic aisle, mention this upfront. Close dialog with potential suppliers by asking for samples, COAs, and references from similar customers in your industry.

The freeze dried fruit market offers tremendous potential in healthy snacking, plant-based foods, and convenient nutrition for busy families. Brands that secure reliable supply now will capture market share as consumer demand continues to climb.

Your next step is clear: begin supplier discussions, request samples of the fruits critical to your product line, and evaluate partners based on quality, service, and alignment with your brand values. The delicious, nutritious potential of freeze dried fruit awaits—and the best suppliers are ready to help you create products your customers will love.